Colored PVD stainless steel panels are a fascinating material choice for architects and designers who want both durability and style.

As representatives of Gage Architectural Products, we’re here to present the GageMetal Colored PVD Designs collection and to share practical advice on how these panels can be applied in real projects. Our role is to make the selection process easier, from understanding finishes to supplying samples that let you see and feel the surfaces in person.

What makes these panels stand out

PVD, or Physical Vapor Deposition, is a process where metal vapor and gases are bonded to stainless steel inside a vacuum chamber. The result is a micro-thin, transparent layer of color that doesn’t add weight but significantly strengthens the surface. For our clients, this means colored PVD stainless steel panels that resist wear while still offering the clean look of stainless steel with a striking color finish.

We often advise designers who are weighing different materials for high-touch areas, and the appeal here is clear: the finish becomes part of the steel rather than something that sits on top of it, so there’s no peeling or flaking to worry about.

Available patterns and finishes

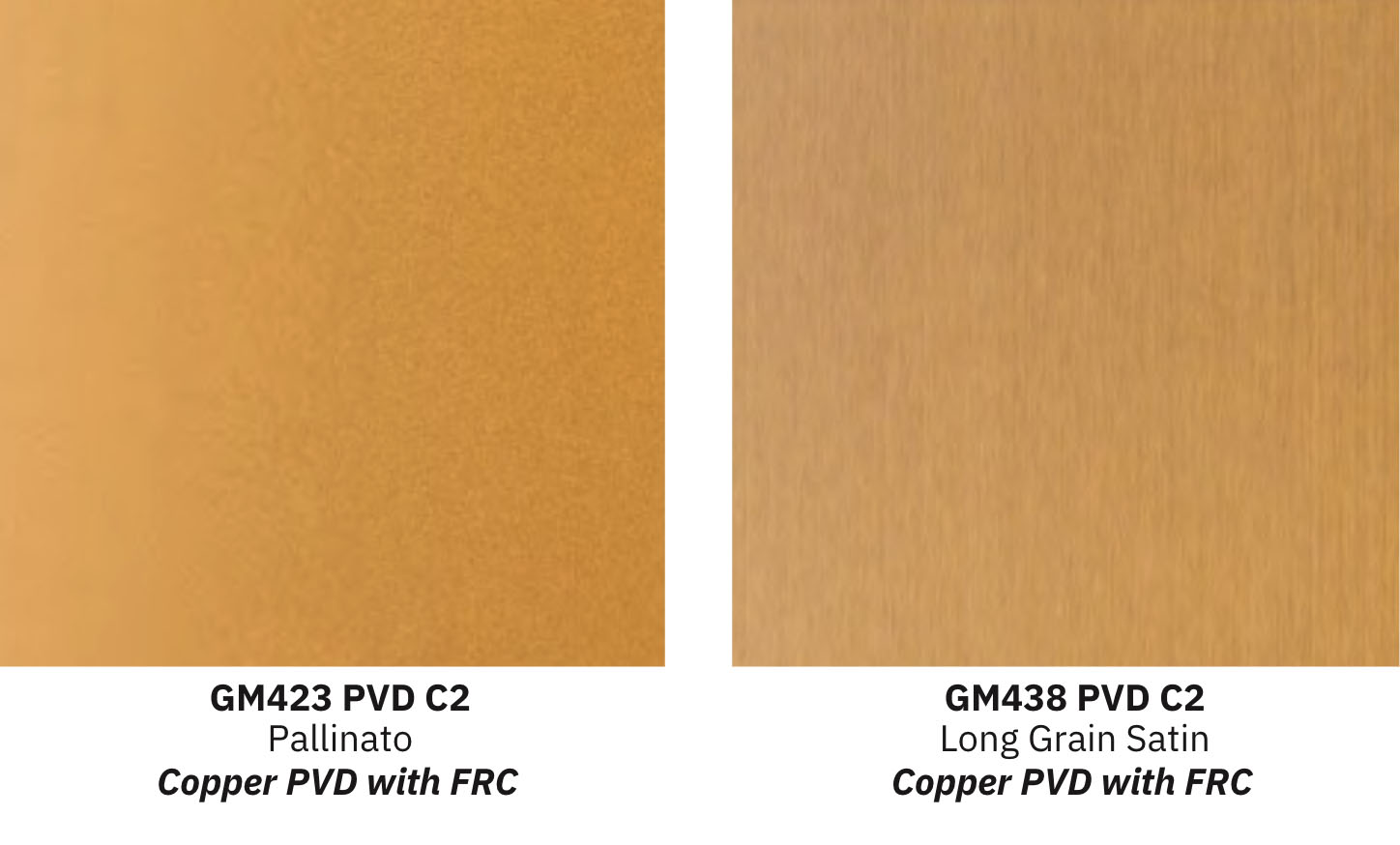

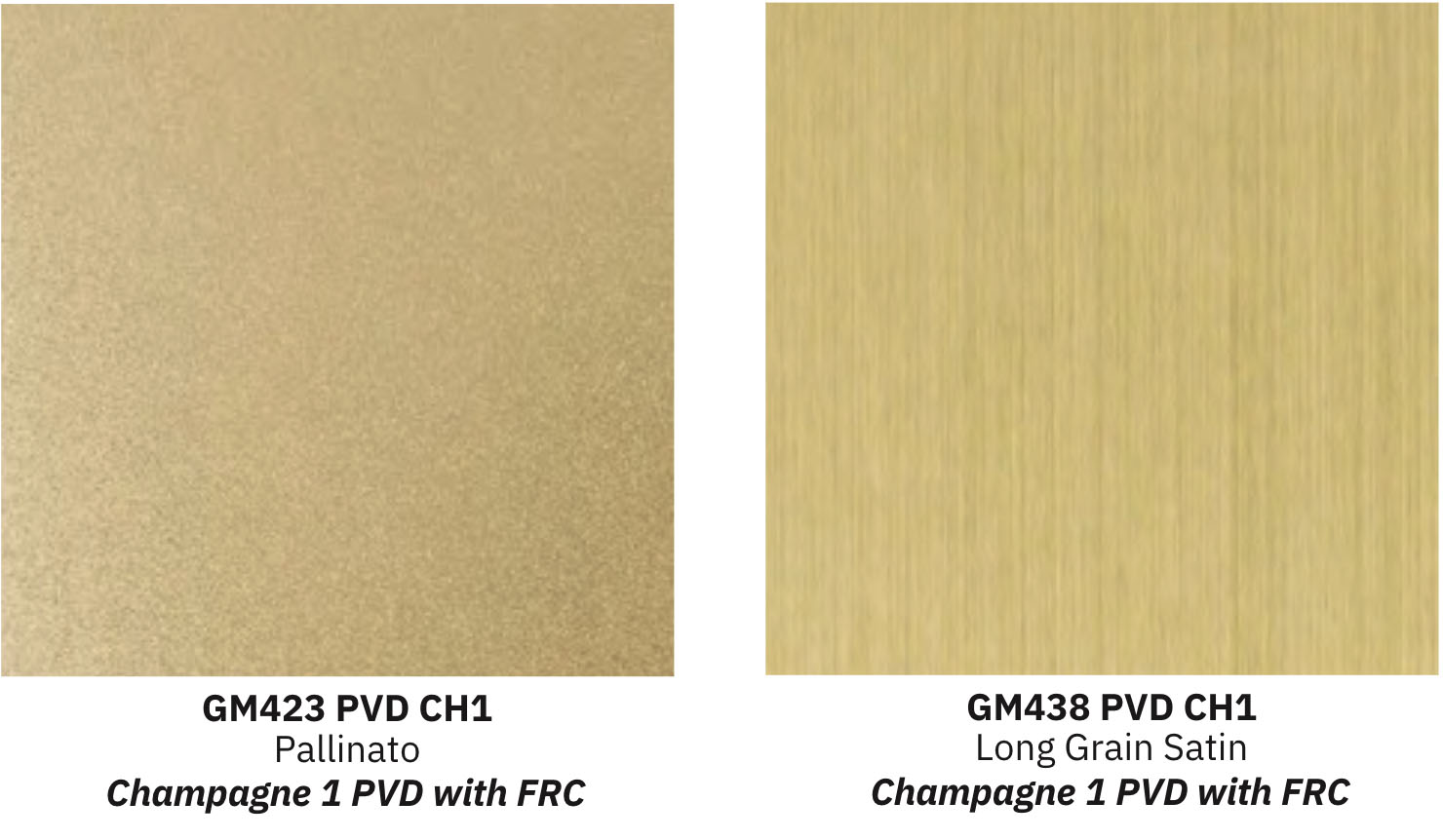

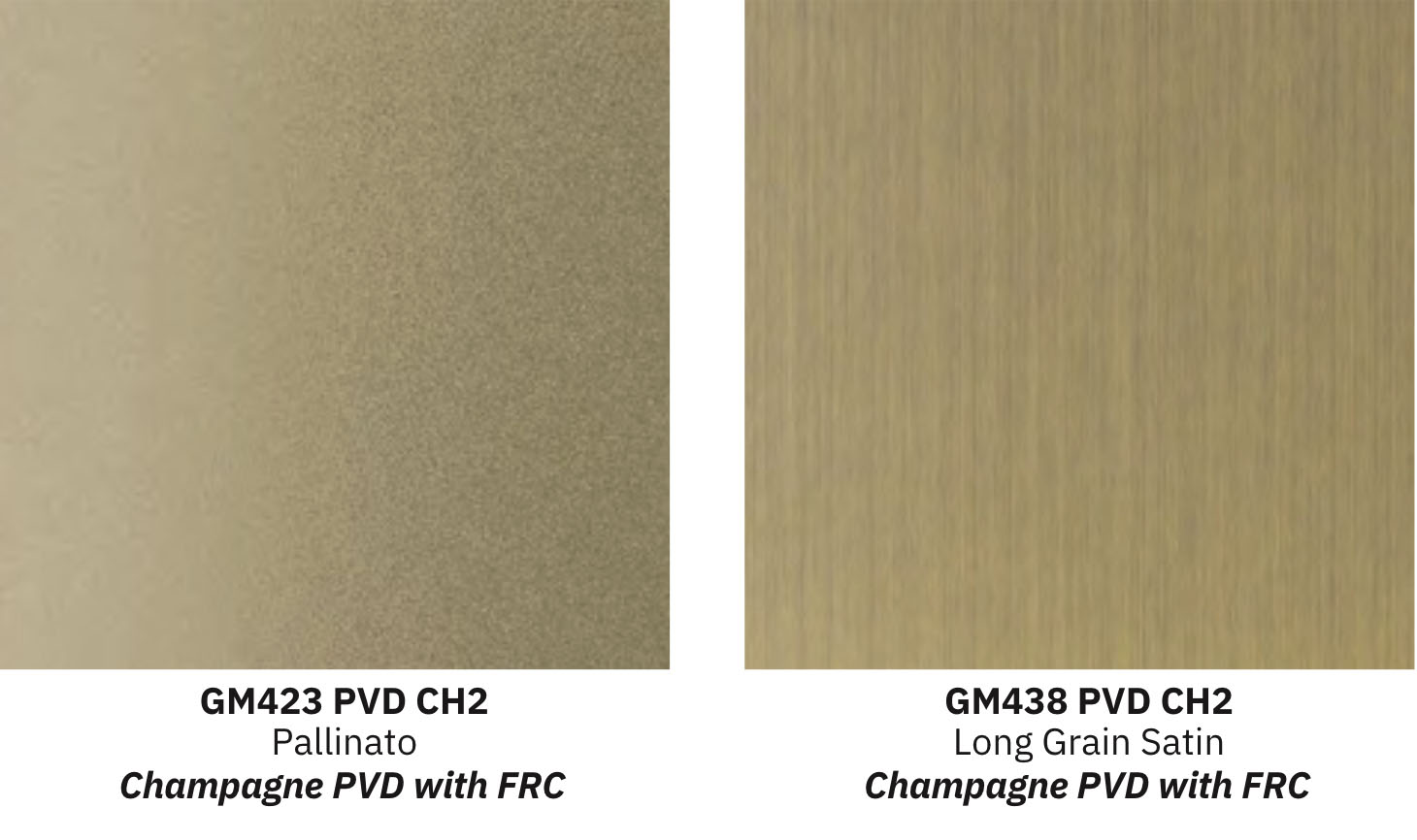

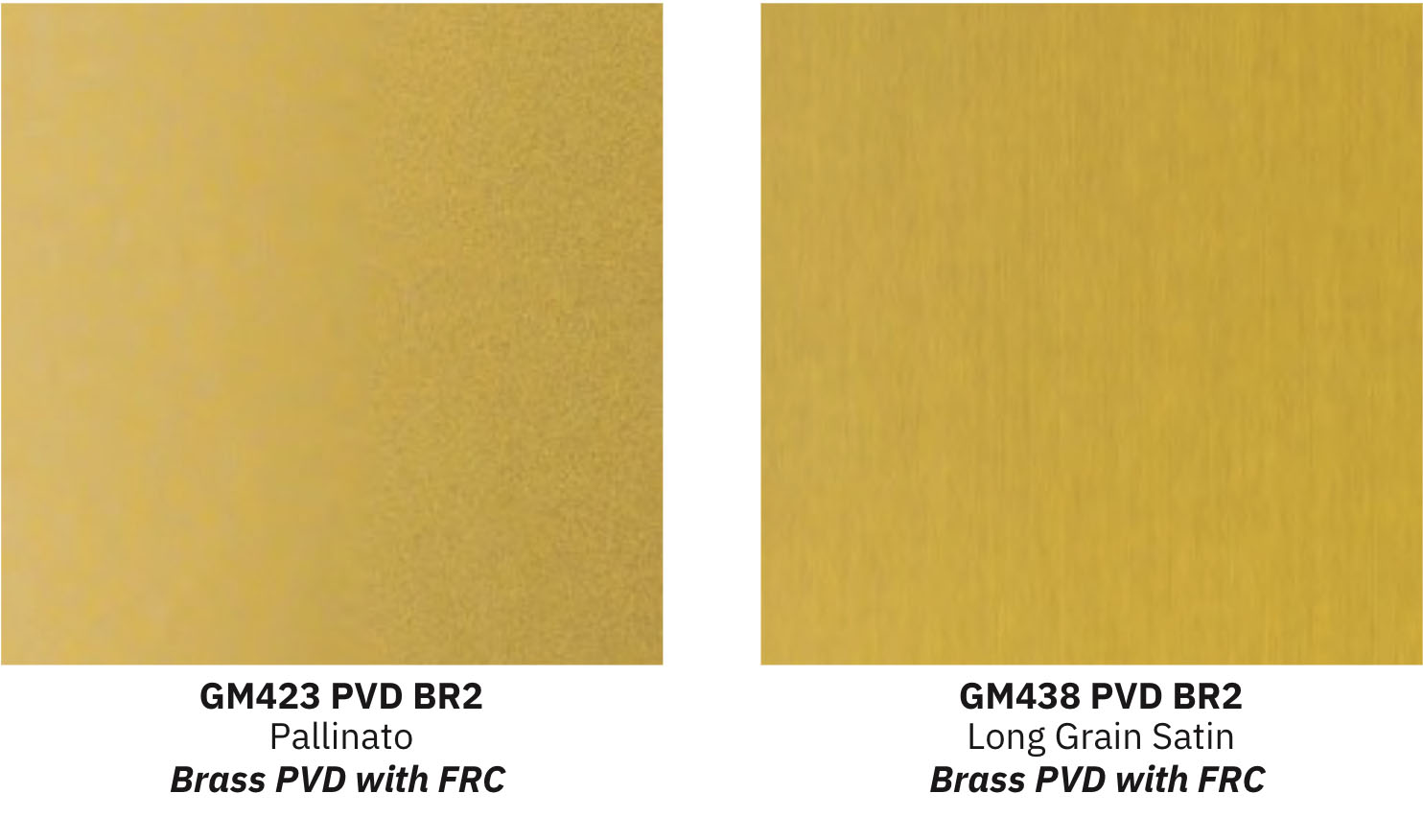

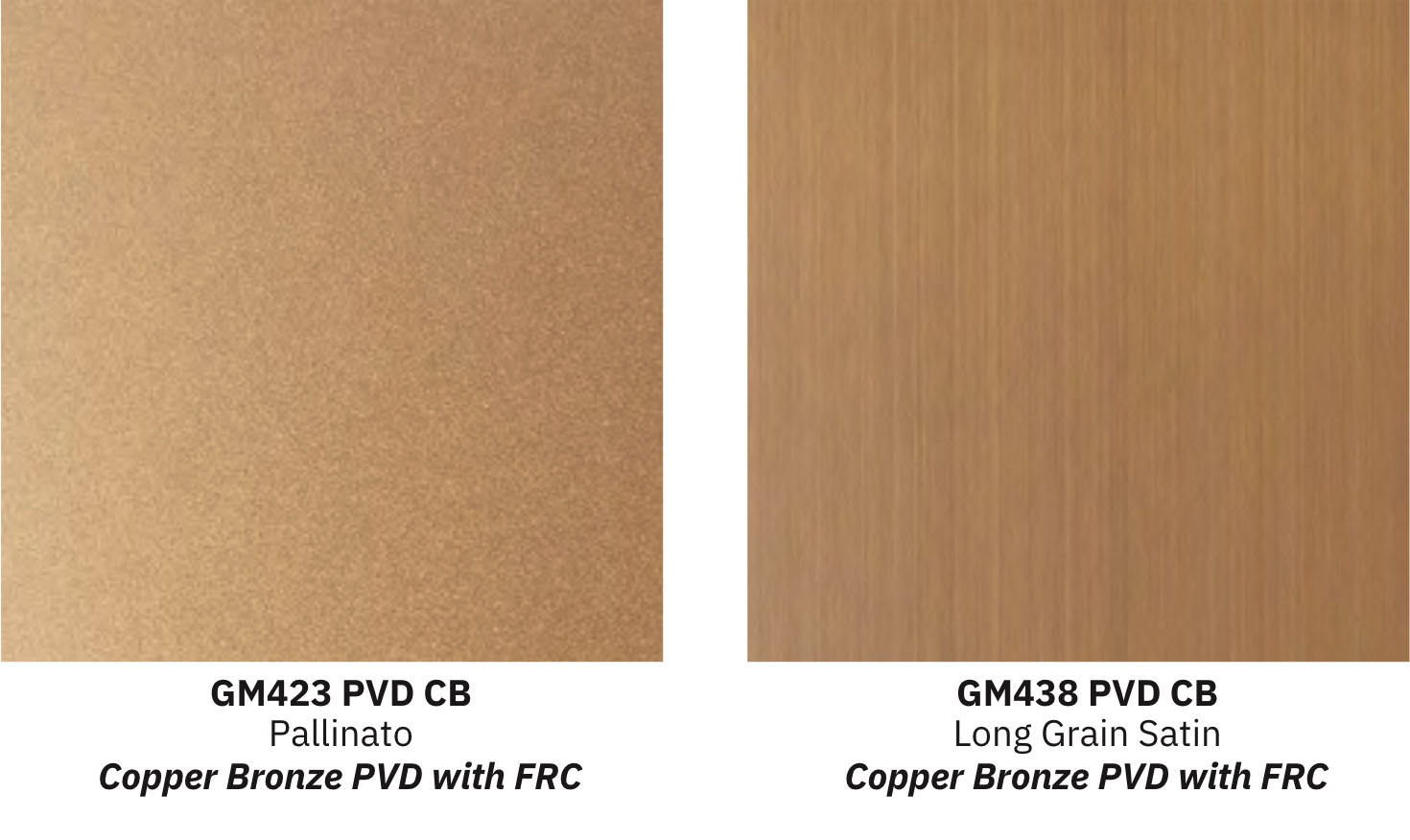

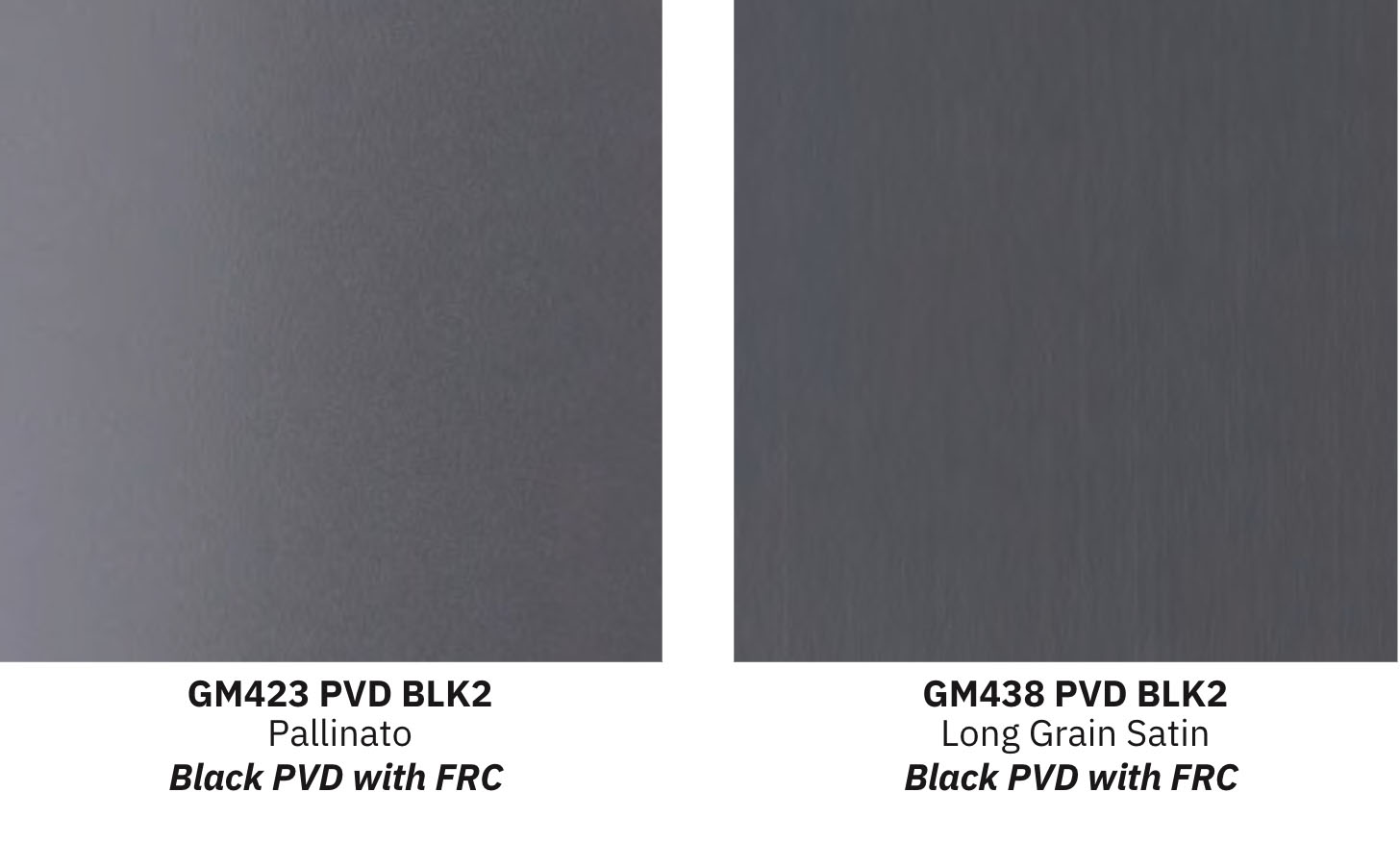

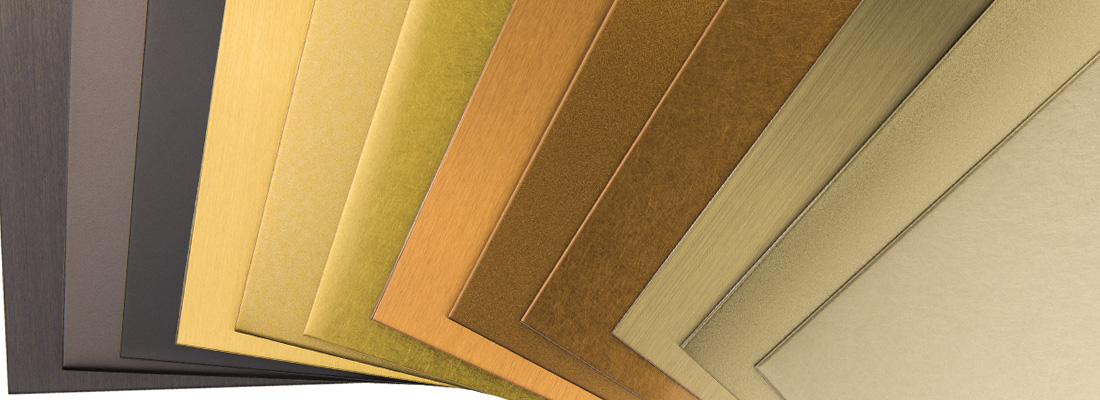

At the moment, two popular designs are available with PVD finishes: GM423 Pallinato and GM438 Long Grain Satin. Each offers a different surface character, and both can be paired with finishes such as Copper, Champagne (in two tones), Brass, Bronze, and Black.

We often suggest looking at several options side by side, since the way light plays on Pallinato is very different from Long Grain Satin. For example, the copper finish on a satin surface gives off a warm glow that works beautifully in hospitality interiors, while black on Pallinato creates a sleek, contemporary statement. Seeing these combinations in person makes it easier to decide which direction to take. That’s why we always recommend requesting samples; photographs can only go so far in showing the true effect of colored PVD stainless steel panels.

Fingerprint resistance for real-life use

One of the practical details that many people appreciate is the Fingerprint Resistant Coating (FRC) that comes standard on GageMetal sheets. In busy spaces, think elevator doors, lobby walls, or retail interiors, smudges and fingerprints can quickly spoil the look of polished metal. With FRC, colored PVD stainless steel panels stay cleaner for longer, and when cleaning is needed, a simple wipe with a mild solution and soft cloth is usually all it takes.

When we show samples to clients, this is one of the first things they notice. It’s not just about the color, it’s about how easy the material is to keep looking its best.

A more environmentally friendly choice

For many of the architects and firms we work with, sustainability matters. The PVD process has an advantage here as well. Unlike other coating methods that generate waste, PVD is considered more environmentally friendly. This makes GageMetal Colored PVD Designs a good fit for projects where eco-conscious decisions are part of the design brief.

Practical details for designers and fabricators

From a fabrication standpoint, the panels are straightforward to work with. Standard sheet sizes are 48” x 96” and 48” x 120”, with 20-gauge thickness being standard and thicker options available by request. They can be cut with a shear, shaped with brake forming, and customized through methods such as laser cutting or water jet cutting.

Contractors also appreciate the fact that the panels can be roll-formed down to a 12” diameter, which is useful for column wraps and rounded features. This flexibility is one of the reasons we recommend colored PVD stainless steel panels for projects that demand both precision and creative freedom.

One of the strengths of PVD is its flexibility. The sheets can be formed to a 90º angle without damaging the finish, which opens up a variety of uses. Elevator doors are a natural fit, but column covers, wall cladding, and decorative features in lobbies and lounges are equally popular. We’ve also seen interest from retail and hospitality designers who want surfaces that can handle constant traffic while still delivering a polished, high-end look.

Because the panels are lightweight yet durable, they can be integrated into both large-scale installations and smaller, detail-oriented designs. For many of the clients we advise, colored PVD stainless steel panels offer a way to bring color and texture into spaces without sacrificing the reliability of stainless steel.

Cleaning and maintenance advice

We often get asked about maintenance, especially for high-touch installations. Thanks to the Fingerprint Resistant Coating (FRC), upkeep is simple. A lint-free cloth and mild soap solution are usually all that’s needed. This makes them particularly appealing in commercial projects where maintenance teams need surfaces that look polished without requiring constant attention. For anyone specifying materials, being able to reassure a client that their new finish won’t be a burden to maintain is an added advantage of GageMetal Colored PVD Designs.

Why samples are essential

Digital images can’t replicate the depth, texture, or reflectivity of PVD finishes. That’s why we always encourage requesting samples. Holding a piece in hand makes the decision process more concrete. You can see how copper reflects warm light or how the champagne tones shift subtly depending on the angle.

As representatives, we’re here to provide those samples directly. If you’re considering colored PVD stainless steel panels for an upcoming project, reach out to us and we’ll make sure you get the finishes you’re interested in.

How we support your projects

Our role isn’t just about supplying sheets. We work with architects and designers at the planning stage to discuss finishes, applications, and even installation approaches. Whether it’s choosing the right texture for a corporate lobby or finding a color that complements hospitality interiors, we’re here to help guide those decisions.

We understand that specifying a material is about balancing performance with design intent. By supplying GageMetal Colored PVD Designs, we make it easier for you to access materials that are both practical and inspiring.

Selecting the right surface finish often comes down to details: how it looks, how it performs, and how it fits into the bigger picture of a project. With colored PVD stainless steel panels from Gage’s GageMetal line, you don’t have to compromise between style and durability.

As representatives, our role is to make the process simple: provide expert advice, share real samples, and supply the panels when you’re ready to move forward. If you’re interested in exploring these designs for your own projects, we’d be glad to help you compare finishes, answer your questions, and get the materials into your hands.

CG Schmitt & Company Inc. is an architectural products manufacturer’s representative sales agency and distributor. We’ve helped architects, designers, and contractors achieve their design and development’s functional and aesthetic objectives since 1994. We provide architectural, interior, and speciality finishes for our clients. Whether you want to discover more about a product or assist in making your design a reality, we are here to assist you. Choose to meet us in person or online, and we will help you in choosing the right product and make your design a reality.